Our process

The FerroSilva process is based on the use of established technologies for biomass gasification, reduction of high value iron ore pellets in a shaft furnace and carbon capture. We combine these three parts in a unique innovative and energy efficient process.

A unique innovative process

We use biomass from local suppliers, e.g. residuals from forestry and agriculture to generate both carbon monoxide and hydrogen gas through gasification. The resulting syngas is then used for reduction, the only known technology that enables a continuous production of fully carburized DRI in large volumes besides using fossil natural gas.

The usage of biomass is the key to energy efficiency, giving us competitive production costs, the high quality of the product and the possibility of being carbon dioxide negative. Our production of reduction gas and liquid biogenic carbon dioxide have a higher added value compared to using biomass the for production of heat and electricity. Furthermore, our process makes it profitable to utilise larger quantities of biomass than has been feasible historically. We create a win-win situation.

Click image to enlarge

Energy-efficiency

DRI is currently produced with fossil natural gas in those parts of the world where it is cheap, such as the Middle East, the Gulf States, North Africa, Mexico and the USA. By collecting and storing carbon dioxide, emissions can be reduced to near zero. A number of projects with this solution are planned, but so far only implemented in one case.

The possibility of using hydrogen, when producing DRI has been known for more than 100 years but has not yet progressed beyond the experimental stage. One problem cited is the technical maturity of electrolysers; another is that the heat balance is more difficult to maintain when using hydrogen than with a mixture of hydrogen and carbon monoxide.

The use of biogenic syngas, which FerroSilva will do, differs from the usage of fossil natural gas and hydrogen in that it enables production of fully carburized DRI and the collection and utilisation of the carbon dioxide formed will be a source of income. It also provides the means to increase the resilience in an society that lacks fossil natural gas and oil to supply the steel industry and the energy sector with important raw material.

Cost comparision between different methods. Source: FerroSilva feasibility study (Click image to enlarge)

A comparison between sources of methods

The figure shows a comparison between the different methods, where the production cost (Y-axis) for DRI produced with fossil natural gas+CCUS (brown), biomass+CCUS (green) and hydrogen (blue) at different natural gas and biomass prices (X-axis) at an electricity price of 32 EUR/MWh and 65 EUR/MWh as shown by the height of the lines. The comparison was made 2022 in our feasibility study together with industrial partners and academics from Chalmers and KTH. Only the price of different kind of energy sources changes in the comparison, while everything else remains constant, such as the price of ore and transport. It´s not exact, but a rough estimate of what a future cost situation might look like. However, there is a relationship between the price of fossil natural gas, biomass and electricity as they can substitute each other and an increase or decrease in one price leads to the others following suit.

The conclusion is that usage of biogenic syngas is energy-efficient and cost-competitive in regions with biomass availability and medium prices for electricity and fossil natural gas.

Life cycle analysis of emissions from the FerroSilva process, including the final step where steel products are produced. Source: Available under read more (Click image to enlarge)

Carbon-negative impact

A life cycle analysis, according to ISO 14044, for steel production using DRI from the FerroSilva process was published in 2023, shows a possibility of creating a carbon sink of 845 kg carbon dioxide per ton produced steel. Initially trees grow and absorb 1205 kg of carbon dioxide from the atmosphere. Subsequent processes create direct or indirect emissions of 360 kg of carbon dioxide. However, if the carbon dioxide is used in products we end up with zero carbon dioxide emissions per ton produced steel. In both these scenarios, the FerroSilva process can potentially have a massive impact on reducing emissions compared both with traditional processes, using coal and blast furnaces and alternative methods using hydrogen or fossil natural gas.

Our process in a nutshell

The FerroSilva process is based on the use of established technologies for biomass gasification, reduction of high value iron ore pellets in a shaft furnace and carbon capture.

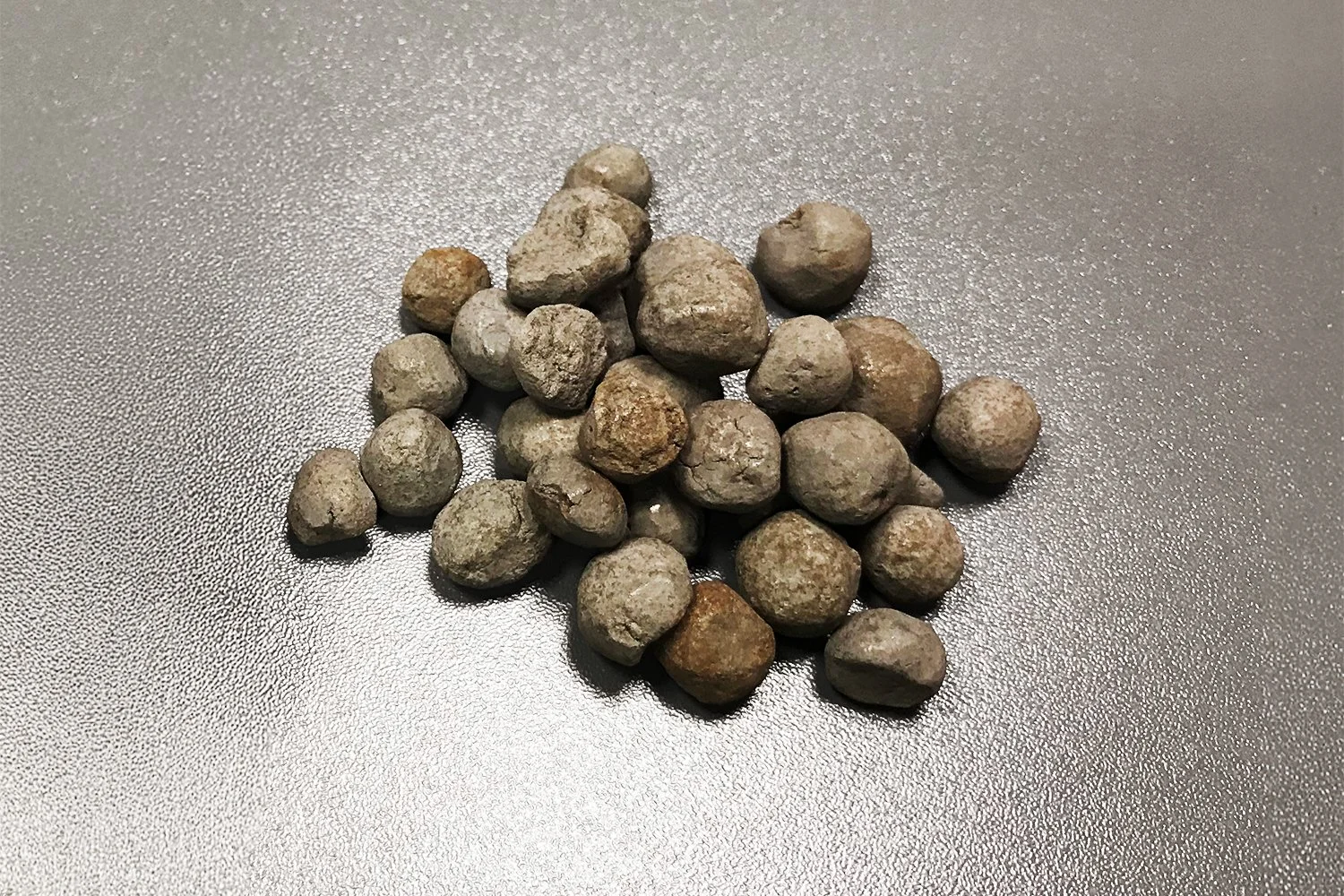

Forestry by-products such as tops and branches are collected, chipped and transported to the plant. As an alternative, other biomass can be used, as for example pulpwood (chipped at the plant) and residual product from agriculture and sawmills (raw chips, dry chips and sawdust). All materials are dried before being gasified in a fluidised bed. The raw gas must be purified from tar, among other things, before the carbon dioxide formed is removed and it can be used as process gas for reduction, known as syngas. The syngas produced in the FerroSilva process has the same composition of carbon monoxide and hydrogen as reformed fossil natural gas, so the same type of shaft furnace process can be used.

Built upon proven technologies

Our production process uses proven basic technologies, while the combination of these is new. This gives us a Technology Readiness Level of +7. The need for electricity is a factor of ten lower than what electrolysis-based methods require and existing electricity infrastructure can be used, enabling rapid scalability.