What we do

We produce high-quality and carbon-negative fully carburized sponge iron (DRI) and a co-product in form of liquid biogenic carbon dioxide. As co-products we also get valuable biochar and excess heat.

Our customers

In the near future, our fully carburized sponge iron (DRI) will be offered to special steel mills, in Sweden and Finland with whom we have off-take agreements. Our liquid biogenic carbon dioxide will be offered to companies in the chemical and energy industries. Biochar and excess heat will also be valuable co-products, which can be used, for example, by steel mills and district heating businesses.

Read more about our cost competitive and energy-efficient process. Besides having the potential of being carbon-negative we will be strengthening our customers competitiveness:

Development of the DRI market. Source: 2024 World Direct Reduction Statistics, Midrex Technologies, Inc. (click image to enlarge)

The challenge we solve

Our development and future growth are enabled by a fast-growing market demand as the figure shows, driven by the transition in the steel and energy industries where resilience and sustainability are in focus. Electric steelmaking, with scrap and DRI will result in lower carbon footprint, compared with traditional processes using coal and blast furnaces, which are responsible for 7-9% of todays global CO² emissions.

Electric steelmaking is the new normal but a predicted shortage of scrap guarantee’s a significant further increase in demand of DRI. The steel industry will therefore probably face a future challenge in getting access to enough DRI and scrap. FerroSilva will help them to solve that challenge and, at the same time, to reduce their CO2 emissions.

Rapid scalability

The setting up of an initial commercial pilot plant will be the first of several steps in establishing our business. This will take place near our customers sites in Finland or Sweden, with whom we have already entered off-take and land-lease agreements. Our goal is to reach an annual delivery capacity of 50 kton, of both fully carburized DRI and liquid biogenic carbon dioxide in 2029 and >500 kton of each product in 2032, when we will have two plants in operation.

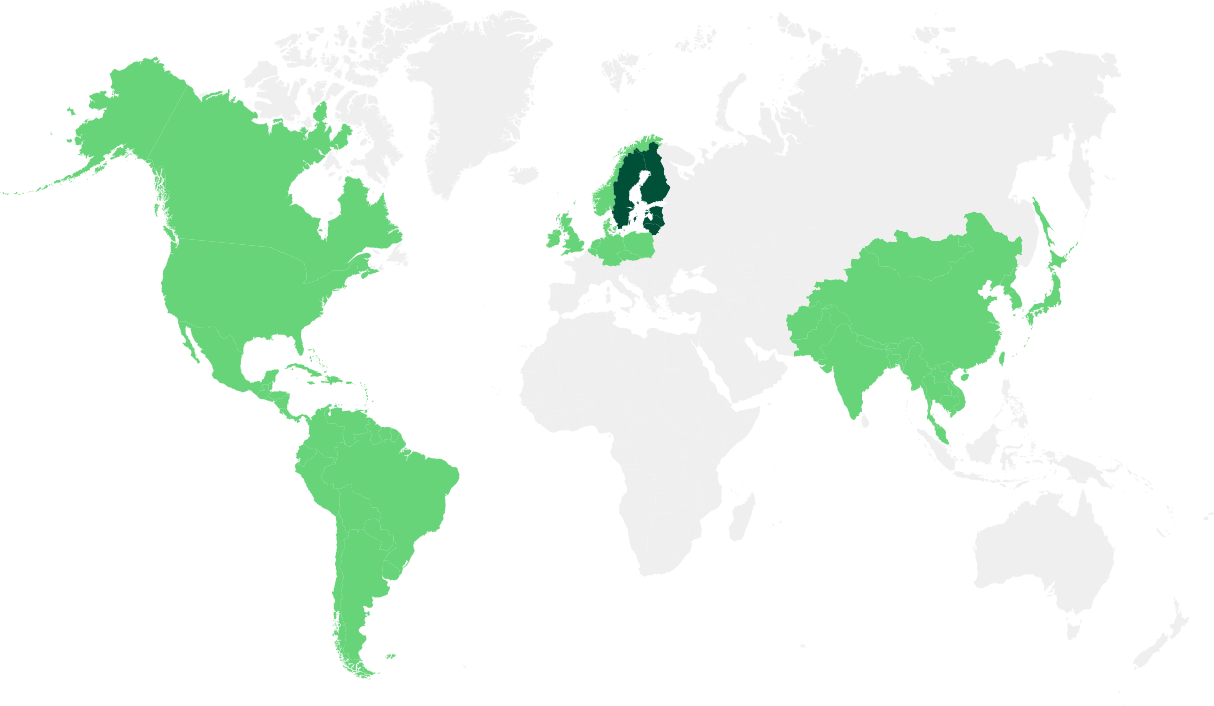

We see significant growth opportunities in Northern Europe, North and South America and Southeast Asia, where our further growth is planned. In these areas there is biomass available and existing special steel mills which, like the mills in the Nordics, will need DRI as complement to scrape for their future electric based production. And the existing electricity infrastructure can be used even here. These conditions facilitate a rapid scalability.